Unknown Facts About Electrical Panel Phenolic Labels

Wiki Article

How Electrical Panel Phenolic Labels can Save You Time, Stress, and Money.

Table of ContentsSome Known Details About Electrical Panel Phenolic Labels Indicators on Electrical Panel Phenolic Labels You Should KnowThe Ultimate Guide To Electrical Panel Phenolic LabelsFacts About Electrical Panel Phenolic Labels RevealedElectrical Panel Phenolic Labels Fundamentals ExplainedThe smart Trick of Electrical Panel Phenolic Labels That Nobody is DiscussingAn Unbiased View of Electrical Panel Phenolic LabelsWhat Does Electrical Panel Phenolic Labels Do?

There are four sets of criteria made use of within the USA that directly address electrical panel labeling somehow. These policies are kept track of and communicated by the Occupational Safety And Security and Health And Wellness Administration (OSHA), American National Specification Institute (ANSI), National Electrical Code (NEC), and the National Fire Protection Organization (NFPA).

This is only an overview, and it is best to consult the laws carefully to discover all the appropriate details needed for your facility. The Occupational Safety And Security and Health and wellness Standards govern every facet of workplace in the united state Within these regulations, a pair of sections are directly pertinent to the security and educational labeling of electrical panels and tools:: "The wording of any kind of indication should be quickly read and succinct.

Things about Electrical Panel Phenolic Labels

While the extent of ISO policies covers an internationally acknowledged criterion, the ANSI criteria have actually been taken on to define requirements within the U.S. There are thousands of ANSI requirements, however the one most vital for electric panel labeling is ANSI Z535 and especially ANSI Z535. 4 American National Requirement for Product Safety Signs and Labels.- In instances where items have a considerable anticipated life or were subjected to extreme problems, the product user must get in touch with either the product supplier or another resource to identify a means for obtaining substitute indications or tags". The NFPA looks after the development of the National Electric Code, and it was lately updated in 2020.

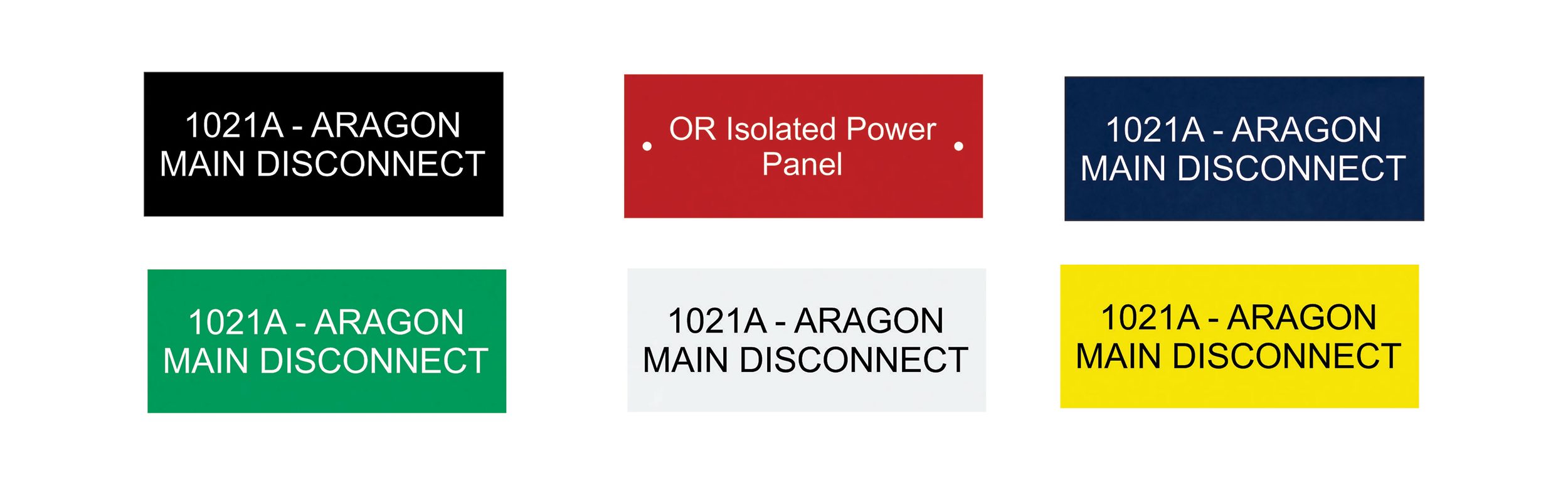

As we covered above, the guidelines established specific guidelines for the sizing, color, and info for your labels. Electric panels come in a variety of shapes and sizes.

A Biased View of Electrical Panel Phenolic Labels

They are ideal for many electric applications and have excellent resilience and readability. Metal labels ought to be picked for applications needing robust durability. One of the best products readily available is Metalphoto photosensitive anodized aluminum, which is made use of for tags and tags that need a service life of over twenty years also in the toughest conditions.In addition to selecting electrical panel labels, your facilities management program ought to additionally include correct maintenance and examination for your equipment and your tags. Gradually tags, may end up being used or obsolete and call for replacement to keep the integrity of your electric system.

Phenolic labels are commonly made use of on electric panels, valves, terminal blocks, as well as personalized applications where phenolic materials are a requirement. Electrical Panel Phenolic Labels. Understood for its capability to withstand greater temperatures, along with its strength and tightness, phenolic items are the perfect option for applications that require thermal resistance or resistance to certain chemicals

Excitement About Electrical Panel Phenolic Labels

Machinery is frequently exposed to rough problems and security dictates that such locations have durable labeling. These examples are reduced out to suit control switches or bars and can be personalized by size, shade and shape.They are ideal for many electric applications and have fantastic toughness and readability., which is made use of for tags and tags that require a shelf life of over 20 years even in the harshest conditions.

In addition to picking electric panel labels, your facilities administration program should additionally entail appropriate upkeep and evaluation for your equipment and your labels. With time labels, may end up being used or check my site out-of-date and call for replacement to maintain the stability of your electric system.

A Biased View of Electrical Panel Phenolic Labels

Machinery is usually exposed to extreme conditions and safety and security determines that such areas have resistant labeling. These instances are cut out to fit control switches or bars and can be personalized by dimension, shade and shape.

They are appropriate for the majority of electric applications and have great resilience and readability., which is made use of for tags and tags that need a shelf life of over 20 years also in the harshest problems.

The Ultimate Guide To Electrical Panel Phenolic Labels

Along with choosing electrical panel labels, your centers administration program need to likewise entail appropriate upkeep and examination for your tools and your labels. Over time tags, might become used or out-of-date and need substitute to keep the honesty of your electric system.Phenolic tags are typically utilized on electrical panels, shutoffs, terminal blocks, as well as personalized applications where phenolic products are a demand (Electrical Panel Phenolic Labels). Known for its capacity to endure greater temperatures, as well as its stamina and stiffness, phenolic items are the ideal solution for applications that need thermal resistance or resistance to specific chemicals

Equipment is typically exposed to extreme conditions and safety dictates that such locations have durable labeling. These instances are eliminated to suit control switches or levers and can be tailored by size, shade and form.

The Only Guide for Electrical Panel Phenolic Labels

They are ideal for the majority of electric applications and have great resilience and readability., which is used for labels and tags that browse around this site require a rack life of over 20 years also in the toughest problems.Along with picking electric panel tags - Electrical Panel Phenolic Labels, your facilities administration program ought to also entail appropriate upkeep and inspection for your tools and your labels. Over time tags, may become used or out-of-date and require substitute to preserve the integrity of your electric system

Phenolic labels are commonly made use of on electrical panels, shutoffs, terminal blocks, along with custom-made applications where phenolic materials are a need. Understood for its capacity to stand up to greater temperatures, as well as its stamina and stiffness, phenolic items are the perfect remedy for applications that require thermal resistance or resistance to details chemicals.

What Does Electrical Panel Phenolic Labels Mean?

Machinery is usually exposed to rough conditions and safety and security dictates that such areas have durable labeling. These instances are eliminated to accommodate control buttons or bars and can be tailored by dimension, color and form.Report this wiki page