Little Known Questions About American Plastics.

Wiki Article

Examine This Report on American Plastics

Table of ContentsThe American Plastics StatementsExcitement About American PlasticsThe Single Strategy To Use For American PlasticsThe 6-Minute Rule for American Plastics3 Simple Techniques For American Plastics

This consideration is particularly essential for applications that involve high-pressure liquids. The scale and scope of the project additionally play a considerable duty in size selection. Bigger jobs may require pipelines with better diameters to effectively distribute liquids over long ranges. Furthermore, elements such as surface difficulty, the potential for ecological stress and anxiety, and the installment atmosphere should influence the pipeline dimension to make sure a successful, lasting application.

Engage with professional advice to confirm your option and adapt as necessary for ideal outcomes. Equipped with this understanding and the actionable actions laid out, you are well-appointed to make educated decisions when choosing HDPE pipeline dimensions for your projects. Your attention to information in this choice procedure will go a long means in guaranteeing the effectiveness, safety, and cost-effectiveness of your piping systems.

Some Known Details About American Plastics

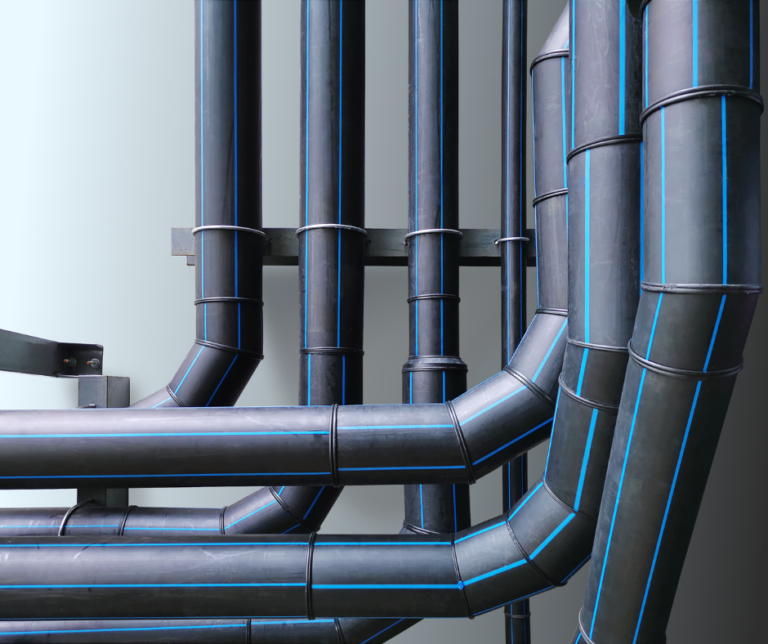

Due to the fact that HDPE is lightweight and chemically inert, it can deal with fluid and gas transportation with very little maintenance. HDPE pipes are extensively taken on across a series of sectors as a result of their versatility and stamina. One of the most typical uses for HDPE pipe is in water system systems. HDPE's corrosion resistance makes it suitable for both safe and clean and non-potable water circulation, whether in community networks or private systems.: HDPE pipelines are signed up with through warmth fusion, developing a seamless, uniform connection as solid as the pipe itself. This watertight joint is important in gas and water distribution, where leaks can cause unsafe circumstances or expensive waste.: HDPE pipes are lighter than standard metal pipelines, making them less complicated to move and set up.

We have storehouses in multiple places to make sure a fast response. You can obtain comprehensive item info and estimates through our main site, by phone, or by e-mail. Our basic and quick ordering process and efficient logistics guarantee you receive your 4-inch HDPE pipe in the shortest feasible time. Our after-sales group is offered 24/7 to assist with any problems you may experience, guaranteeing tranquility of mind.

PE 80 is for easy commercial applications like gas and water, while PE 100 supplies lasting toughness and performance for tougher usages. For a succinct appearance at applications, below are several of one of the most usual kinds of HDPE piping and their applications. Piping systems utilize PE 32 or PE 40 for low-pressure applications.

The Only Guide to American Plastics

PE 80 has a material resistant to cracks, so it appropriates in applications susceptible to splitting, like sewage systems and water distribution lines. PE 100 is likewise resistant to fractures, and 100 N/mm2 is the minimum needed toughness. As mentioned, classifications of HDPE piping include small stress, product, and color coding.

Makers produce pipes with various stress qualities (PN grades). This shows the stress in bars the pipeline can sustain with water at 68 levels Fahrenheit. The stress qualities comply with European criteria, and they are: PN 2.5 max pressure 2.5 bar PN 4max stress 4 bar PN 6max stress 6 bar PN 10max pressure 10 bar PN 16max pressure 16 bar The color codes that indicate the stress quality are yellow for PN4, red for PN6, blue for PN10, and eco-friendly for PN16.

The complete list of dimensions is extensive. Pipe vendors use sizing guides with added info like wall thickness and mass. Quality control follows ISO standards managing the material design and minimum required toughness (MRS) of pipes. Normally, top quality assurance examinations inform the suppliers if the HDPE pipes can offer 50-plus years of solution under regular operating conditions.

Industries consider small stress, material, and various other elements when identifying which pipelines to utilize - hdpe pipe suppliers Midland TX. Today, you'll see high-density polyethylene pipelines in water, gas distribution, farming, and a lot more. Industries use PN 10 quality HDPE pipeline for water supply and distribution networks. You'll typically see it in multistory apartment building.

Some Known Factual Statements About American Plastics

Mining firms utilize pipes for slurry transport and dewatering. HDPE piping can protect cords in the telecommunications industry. This is advantageous for below ground cable televisions. The very best component is that services can make use of basic PN course pipelines for this application. Industries choose HDPE piping over standard pipelines due to the fact that they offer a lot more advantages.

For beginners, HDPE pipelines are extremely sturdy and can last a long time with marginal maintenance. HDPE pipelines are lighter than conventional pipelines for much better handling and transport.

Excitement About American Plastics

Whether you're a service provider, engineer, or DIY enthusiast, this post will provide you with the expertise useful reference to make enlightened choices and attain optimal results. When it involves choosing the appropriate HDPE pipeline for your task, comprehending the PSI ranking is of utmost importance. The PSI ranking determines the stamina and stress capability of the pipe, indicating just how much stress it can withstand without failure.The PSI ranking of an HDPE pipeline determines its capability to manage different stress levels. Pipelines with greater PSI scores can hold up against higher stress, making them appropriate for applications that entail greater liquid or gas pressures. On the various other hand, pipes with lower PSI scores are optimal for low-pressure applications.

Report this wiki page